GREEN TECHNOLOGY

We build a world where people live together in harmony with technologies which let the nature breathe.

Bumper Beam

Fender & Member

Dash

Fender & Member

Center Floor

Rear Floor

Back

Front Door

Rear Door

Side

Quarter

Hood

Trunk Lid

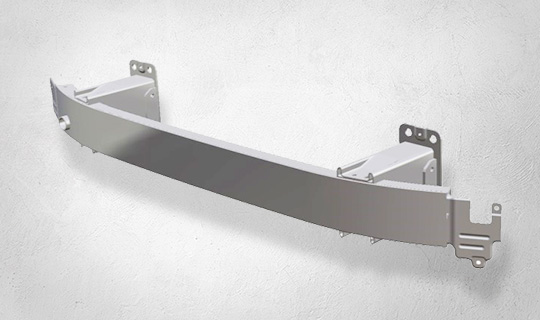

FRONT BUMPER BEAM

- It reduces shock at low-speed collision and protects passengers. Various sensors needed for autonomous driving are connected.

- Using 7000 series aluminum alloys, we have lightweighted and enhanced crash performances.

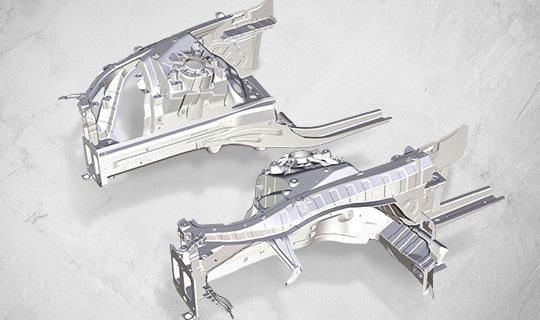

PNL ASSY-F/APRON & MBR COMPLETE

- As a key longitudinal member for the car front, it absorbs shock at front collision and absorbs and delivers load from road surface vibration at front.

- It is lightweighted by aluminum die-casting and extruded aluminum alloys. With aluminum-steel assembly engineering, mechanical joining such as SPR, FDS and REW is applied.

PNL & HINGE ASSY-HOOD

- It determines front design, protects an engine room and absorbs shock for pedestrian protection.

- Aluminum plate and SPR for aluminum bonding are applied for lightweighting.

- It adopted a clamshell structure (covers up to the fender) for the first time in the Republic of Korea and satisfied design extension for luxury cars.

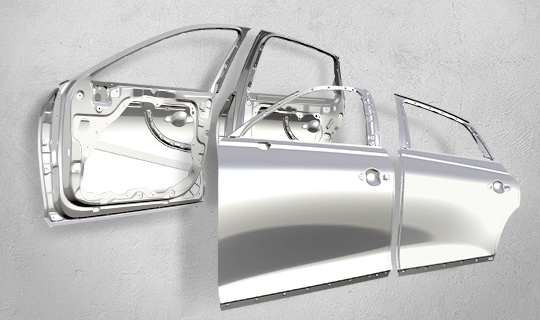

PNL ASSY-FRONT & REAR DOOR

- The doors are positioned on car sides. They divide the inside and outside of the car when a passenger gets in and out of the car. They absorb shock and protect passengers.

- Aluminum plate and extruded aluminum alloys are applied for lightweighting. In addition, laser, SPR and aluminum spot are adopted for joining.

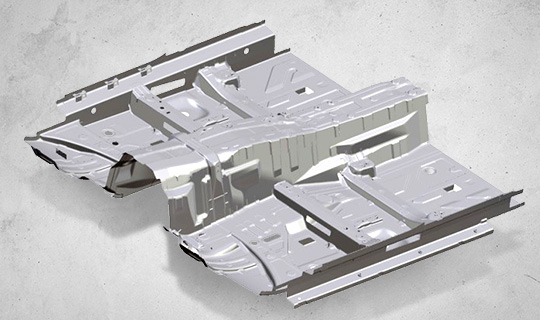

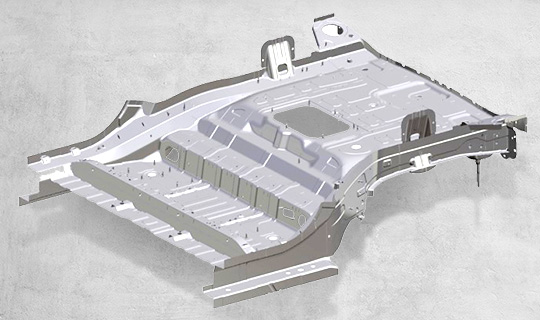

PNL ASSY-CTR FLOOR COMPLETE

- This structure is designed to keep a passenger’s room intact at front/side collision. It is required to shield water, dust, heat and noise. It assembles car seats, driving units, exhaust and braking systems and EV batteries.

- For structural stiffness, lightweighting materials and new-forming procedures (e.g., CFRP, aluminum extrusion, die-casting, hot stamping, roll forming, etc.) are applied.

PNL & MBR ASSY-RR FLR COMPLETE

- A major skeleton member for the rear part of a vehicle, this part keeps a passenger’s room intact at rear-end/-side crash. It assembles rear seats, fuel tank, EV batteries and others.

- For structural stiffness and lightweighting, lightweighting materials and new-forming procedures (e.g., hot stamping, roll forming, aluminum extrusion, die-casting, etc.) are applied.

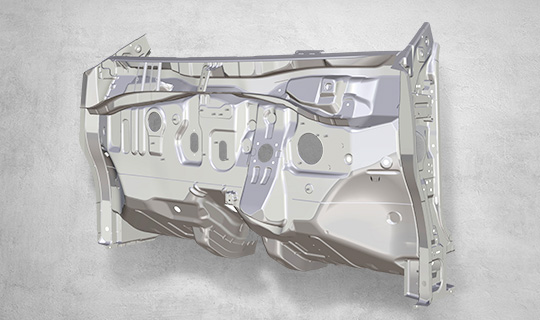

PNL ASSY-DASH COMPLETE

- Dividing an engine room and a passenger’s room, this structure is designed to support car body load at front. In particular, it requires soundproof, dustproof, watertight and insulated features. For assembling interior materials, it adopts a cowl cross bar.

- It adopts hot stamping forming technologies needed to enhance the performances of skeletal structure.

PANNEL ASSY-TRUNK LID

- It determines the design of a rear part and is used as the cover of a trunk space.

- For lightweighting, aluminum plate and extruded aluminum alloys are applied. In addition, it adopts SPR, aluminum spot and brazing for joining.

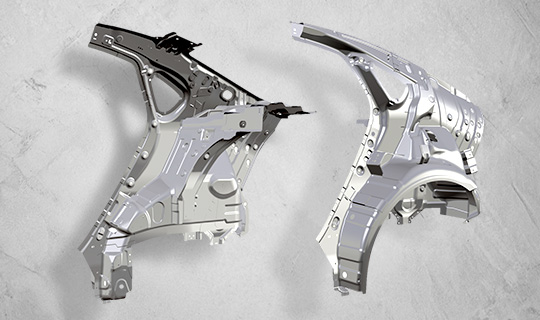

PNL ASSY-QUARTER INR COMPLETE

- As the structure supporting the stiffness of a rear part, it absorbs and delivers load from road surface vibration in the rear part.

- It adopts aluminum die-casting for lightweighting and SPR for joining.

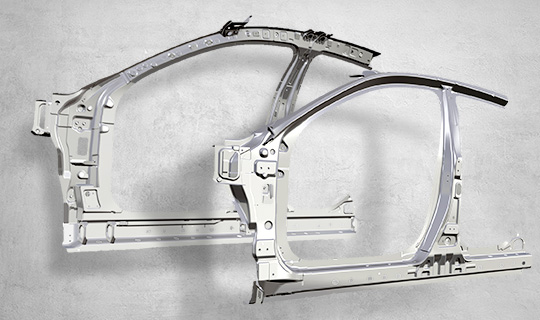

REINF ASSY-SIDE COMPLETE

- As a major skeletal unit supporting the front part and a passenger’s room, it endures vehicle load when a car is rolled over. It is designed to absorb shock at front/side collision. It offers mounting points for door assembly.

- It adopts ultra-high strength steel forming technologies such as roll forming and hot stamping for the improvement of car performances.