GREEN TECHNOLOGY

We build a world where people live together in harmony with technologies which let the nature breathe.

SPECIFIC PROCESS CHART

-

01

01Coil Warehousing (Unloading)

-

02

Slitting Line

A process to cut steel sheet in replacement specification (warehousing specification) according to original specification (purposes)

-

03-1

Blanking Line

A process to cut steel sheet which has been slit by the slitter in the preset form

-

03-2

TWB Laser Welding Line

A process to join two different materials, using laser beam; adopted new TWB technology which has overcome the limitation of conventional spot welding

-

03-3

Roll Forming Line

A process in which 12-20 rolls with same diameter are placed at a proper position and steel sheet is passed through them

-

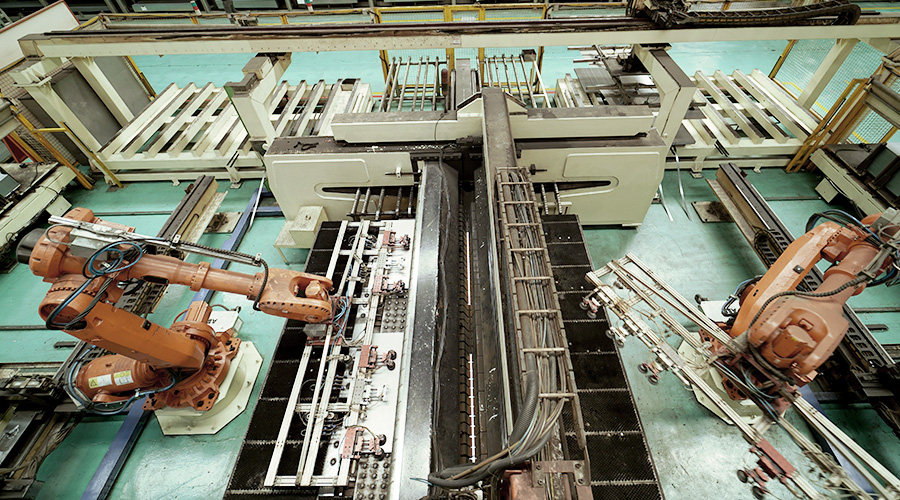

04

Press Line

Mold with a shape of car component assembled between the press forming units which come up and down to produce products through plastic deformation

-

05-1

Hot Stamping

A process to manufacture advanced high-strength steel (1500MPa or higher) by press-forming and cooling boron steel which has been heated at 900ºC or higher temperature

-

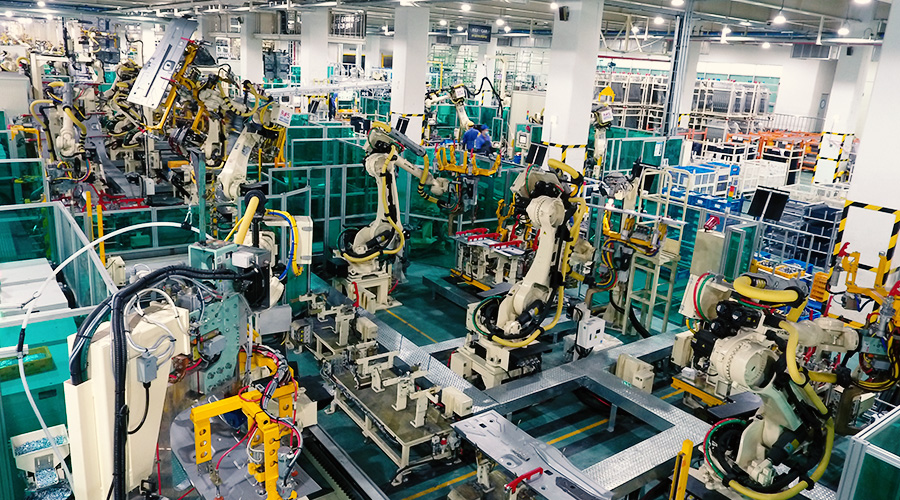

05-2

Assembly Line

A process to assemble and weld panels which have been produced through forming lines

-

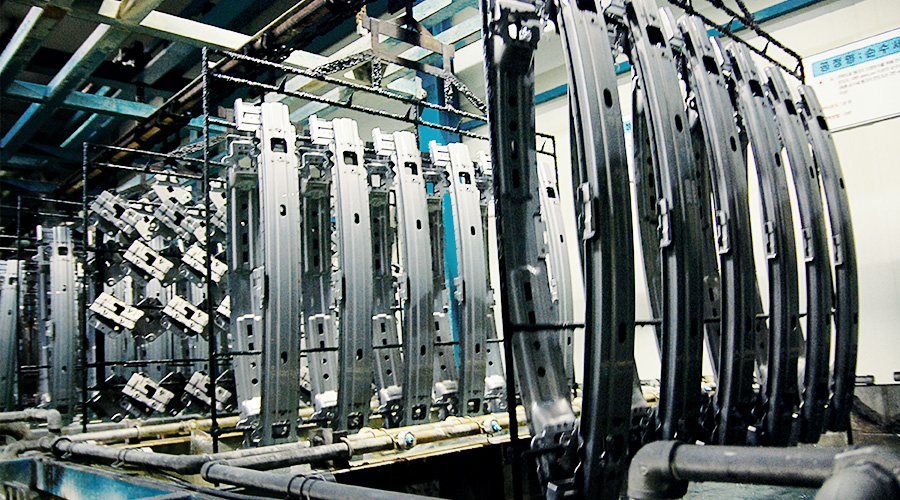

06

Electro-Degradation Coating Line

A process to coat the surface by supplying DC power to water-soluble electro-deposition paints by dividing the product and electro-deposition tank into the anode and cathode

-

07 Release

07 Release